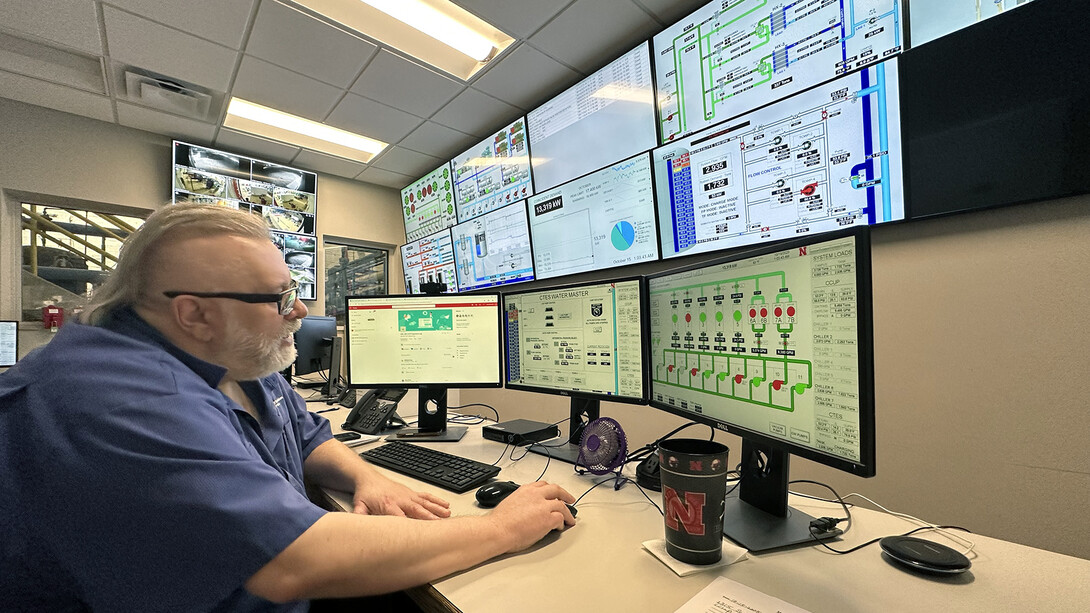

Surrounded by the thrum of massive boilers and chillers, Kenneth Smith keeps the University of Nebraska–Lincoln running through the night — spotting problems before they start and ensuring comfort and business continuity across campus.

A utility senior operator, Smith works the night shift in the utility plant on City Campus, monitoring critical systems that supply heating and cooling across the university. Success for the team Smith has been a part of for 25 years means campus life — from students pulling all-nighters to researchers monitoring projects — moves forward without major interruption.

“Automation handles a lot of it now, but we still need to be here, paying attention,” Smith said. “We can see the status of chillers, blowers, boilers — everything — right from these screens, but it still takes people to make sure things are running the way they should.”

Smith and his colleagues combine high-tech digital monitoring with years of hands-on experience to keep operations running smoothly. Over time, he’s developed a kind of sixth sense for the plant, often hearing subtle changes before alarms get a sniff of trouble.

“You get used to how things should sound when they’re running right,” Smith said. “Sometimes you hear a difference before the alarms even go off. That’s when you know to check it out.”

Whether checking the conductivity levels in the boilers or logging hourly performance data, the work demands technical knowledge, attention to detail and the ability to troubleshoot in real time. Even as much of the plant’s operation has moved to digital systems, Smith’s familiarity with the old-school equipment gives him an edge.

“The chillers used to be run with hand cranks,” he said. “Guide vanes were adjusted manually. Now it's digital, but you still need to know what you're looking at.”

Over the years, Smith has witnessed major changes — from campus construction and plant automation upgrades to the shift from analog controls to today’s advanced systems. But the mission has remained constant: deliver consistent heating and cooling so campus can function year-round.

“We’re always here — holidays, weekends, nights,” Smith said. “The boilers still need to run over Christmas break. If they didn’t, pipes could freeze, and that would be a huge problem.”

Smith’s work supports much more than classroom comfort. Temperature-sensitive experiments, student residence halls, dining operations, data centers and athletic facilities all rely on the systems he helps manage.

“This is my world,” Smith said. “I don’t get out around campus a lot, but I know we’re helping everyone else do what they need to do.”

The utility plant operations team works on a rotating schedule to ensure a minimum of two people are on-site at all times. The team uses a computerized maintenance management system to log anything unusual — whether it’s a chiller leak, minor alarm or equipment in need of attention.

“You can have a nuisance alarm, or you can have something serious,” Smith said. “Either way, you’ve got to check it.”

While the work often happens out of sight, the impact is felt across campus. Without Smith and his team, essential systems would stall — leaving buildings and high-energy systems without heating or cooling, disrupting daily classes and halting research projects midstream.

“I love this job and the university because I get to work with some amazing people,” Smith said. “It’s a great job. It makes me feel like I’m doing something important, something that helps others.”