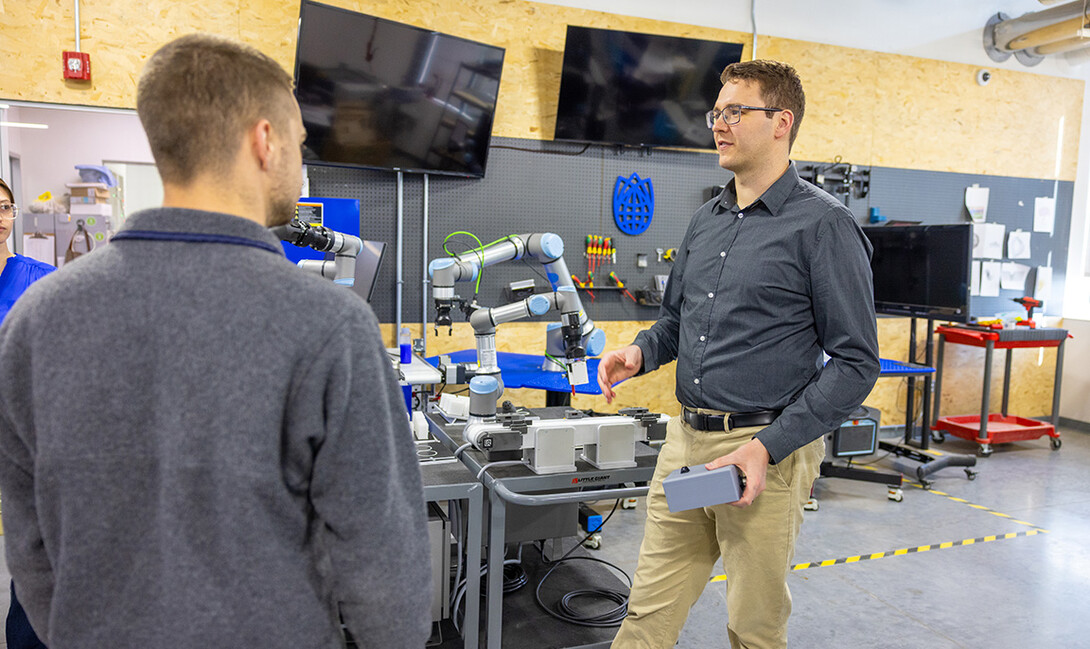

A prototype, idea, doctoral thesis and sketch are all becoming tangible devices and products through the Nebraska Innovation Studio’s inaugural Robotics Fellowship Program.

The five-month fellowship wraps up in May and all four fellows are ready to take the next step toward commercialization — whether that be pursuing external funding or beginning the patent process.

John Strope, program coordinator for Nebraska Innovation Studio robotics, said this first iteration of the fellowship program exceeded expectations.

“When you’re doing something completely new like this, there is a hold-your-breath moment of hoping that it takes off,” Strope said. “The response was incredible, and what the fellows have achieved in such a short amount of time is astonishing.”

Husker alumnus Riley Reynolds, now a surgical robotics engineer with Virtual Incision, started the fellowship with an idea he explored in a master’s degree project several years ago. That idea blossomed into an automated trocar placement device to enhance the safety and precision of laparoscopic and robotic abdominal surgeries. With the product developed during the fellowship, Reynolds plans to pursue a patent.

“I didn’t have a prototype or anything when I started,” Reynolds said. “Now, I have the device. I have it working probably 85% of the way, and my goal at the end of this program is to have a fully functioning device that we can test.”

Amlan Balabantaray, a doctoral candidate in biological systems engineering, applied to the program wanting to take a design from the pages of his doctoral thesis to a working mechanical weed control system. His See and Till system uses cameras, artificial intelligence and a tilling mechanism to target and remove weeds from agricultural fields. With a prototype nearly finished and through the mentorship offered in the program, he is thinking bigger and may pursue commercialization.

“As a part of this program, we got to talk to a lot of people and entrepreneurs, and I feel like this is a very good opportunity where I can take this and maybe have a business of my own,” Balabantaray said. “The first, and best, thing I got from this program were the connections.”

Reynolds, a Utah native, agreed.

“I moved here about two years ago, and having mentors through this program and getting that network and roots planted here has been really beneficial,” he said.

Without the fellowship, Balabantaray did not think he would have developed a prototype, mostly because of a lack of time. The extended access to Nebraska Innovation Studio helped solve that problem for Balabantaray and for Brooke Bode, another fellow in the program.

“What I really liked about the program is that I got extended access to the studio,” said Bode, a senior mechanical engineering major from Hershey, Nebraska. “I get the chance to come in here when it's not technically open and work on things and ask a lot of questions. One of the biggest things I've gained is the ability to ask questions with no barriers. I previously had a membership to work on this project, but I made very little progress because I was scared to ask questions.”

Bode was able to redesign and fine-tune her prototype for the Cattle Kettle Monitor, a product she is developing to automate water management for cattle producers.

“The original prototype worked really well for about three weeks, and then we put it out with cattle, and they destroyed it,” said Bode, who is also a University Honors and Raikes School student. “Cattle are probably the most difficult customer that I will ever have to work with, because if you cross an elephant with a toddler, you get a cow. They chew on everything. They push really hard. They're just really curious and big.”

The extra time — and the allocation of $2,500 in monetary resources for supplies — was also beneficial for Teresa Monsees, a senior mechanical engineering major from Harrisburg, Nebraska. Having a deaf family member inspired her to take flash card sketches into the future with an interactive robotic toy that could help deaf children and their family members learn sign language.

“It’s really hard to find toys specifically for deaf children, and I’ve had this idea for about a year,” Monsees said. “Until this fellowship, I didn’t have the means or the time to work on it.”

Over the course of the fellowship, Monsees was able to 3D print and wire a robotic hand that will be able to sign the alphabet in American Sign Language when the programming is finished.

“The end goal is to have a small doll that will be able to sign along with kids as they read to them. With the fellowship, I want to have a minimum viable product — something I can show to people to say, ‘This is what it does, and how it works, and what we need,’” Monsees said. “Signing incorporates pacing and even facial expression and lots of movement. When you're looking at static imagery on cards, it's really hard to grasp how to do the whole sign.”

The NIS Robotics Fellowship Program was piloted through the Heartland Robotics Cluster. The cluster was established following a grant from the U.S. Department of Commerce’s Economic Development Administration in 2022 and is a collaboration of the University of Nebraska–Lincoln, Nebraska Engineering, Invest Nebraska, the Combine, Nebraska Manufacturing Council, Nebraska Extension, Northeast Community College and Metro Community College to expand training, research and implementation of robotics and grow Nebraska’s economy.

With the grant expiring, Strope said they are seeking financial support from various partners to establish funding for future cohorts, with a goal of offering the program each fall and spring semester.

“This was our inaugural pilot program, and the impact has been incredible,” Strope said. “We’ve received really positive feedback from everyone. I can't wait to see where things go from here.”

Share

News Release Contact(s)

Related Links

Tags

High Resolution Photos

HIGH RESOLUTION PHOTOS

HIGH RESOLUTION PHOTOS

HIGH RESOLUTION PHOTOS